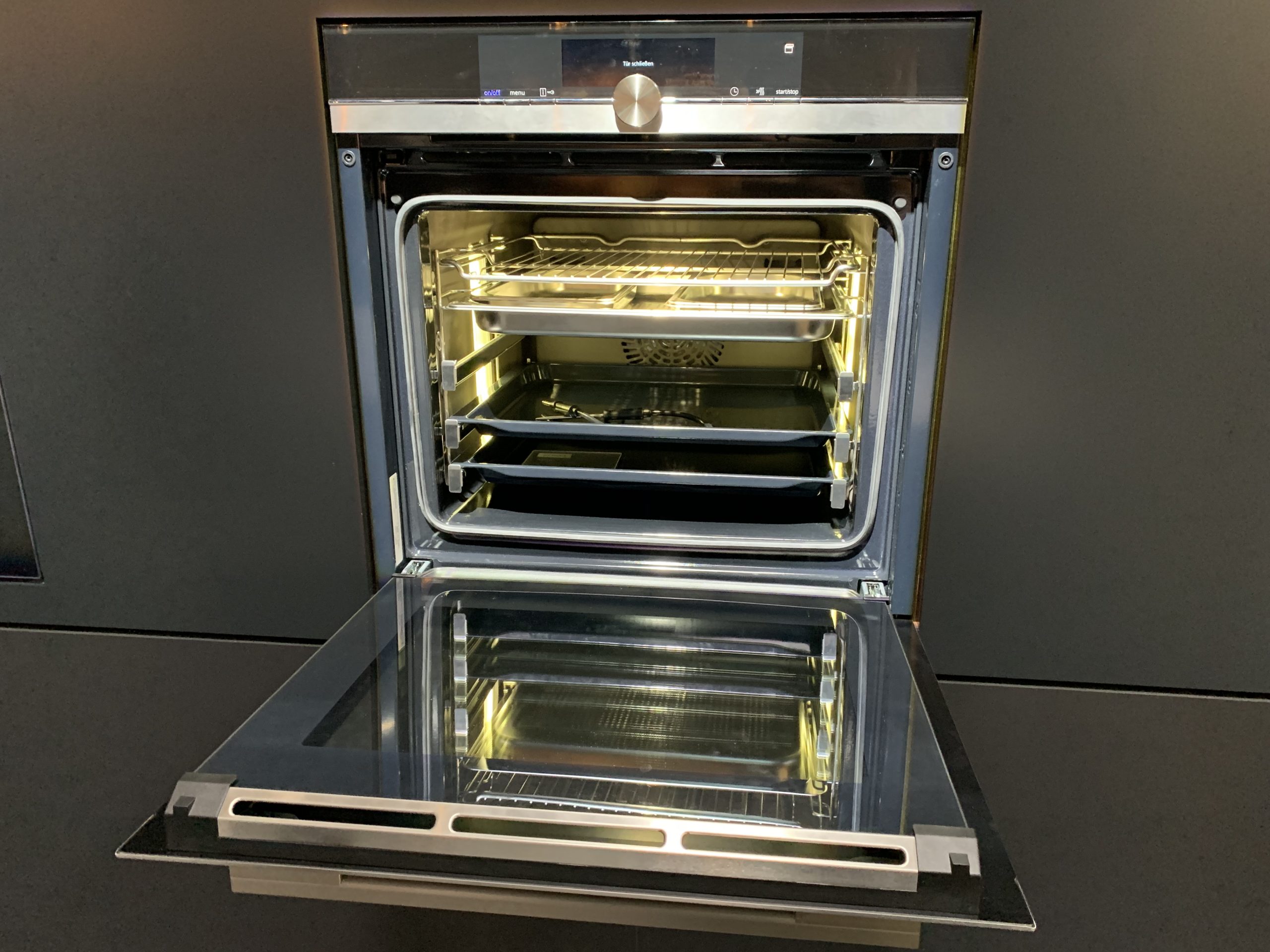

The main application of ELECTA® Borosilicate Glass in the household appliance sector is the production of inner doors for pyrolytic ovens.

The pyrolysis process allows the carbonization of all fat residues present in the oven cavity generated during the cooking, and is obtained by bringing the temperature inside the cavity up to 500 ° C and maintaining it for cycles of 1.5- 2.5 h.

To the glass component is therefore required to withstand these temperature conditions and maintain its properties over time.

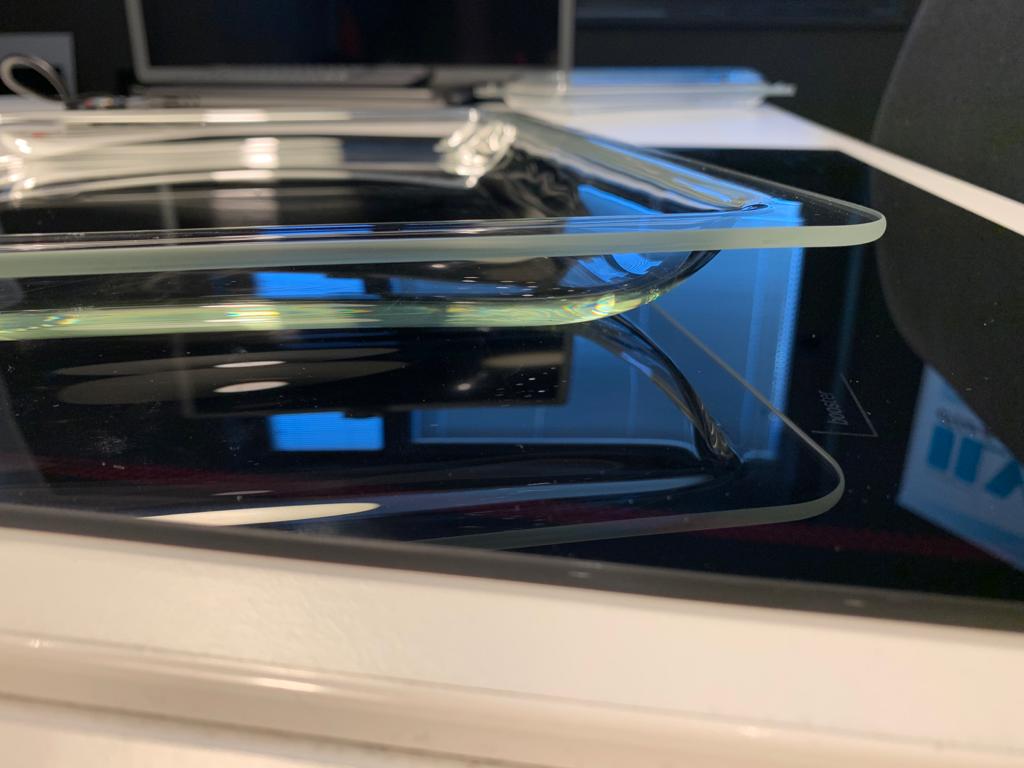

ELECTA® Borosilicate Glass is the raw material that has the best characteristics to perform this function compared with other types of glass.

For this reason, 60 cm and 90 cm oven doors are obtained from borosilicate sheets (e.g. for the US market or for the professional cooking sector).

Borosilicate glass can be transparent or be subjected to screen printing. The process of screen printing on borosilicate glass is particularly complex, and has been developed by ILVA Glass during the development of the product over the last 10 years. As well as the heat treatment process of the finished component, which gives particular characteristics of resistance to temperature and mechanical shocks.