The Low-Emissivity glass consists of a float-based glass on which metal coatings that have the property of reflecting the infrared are applied to one or both faces.

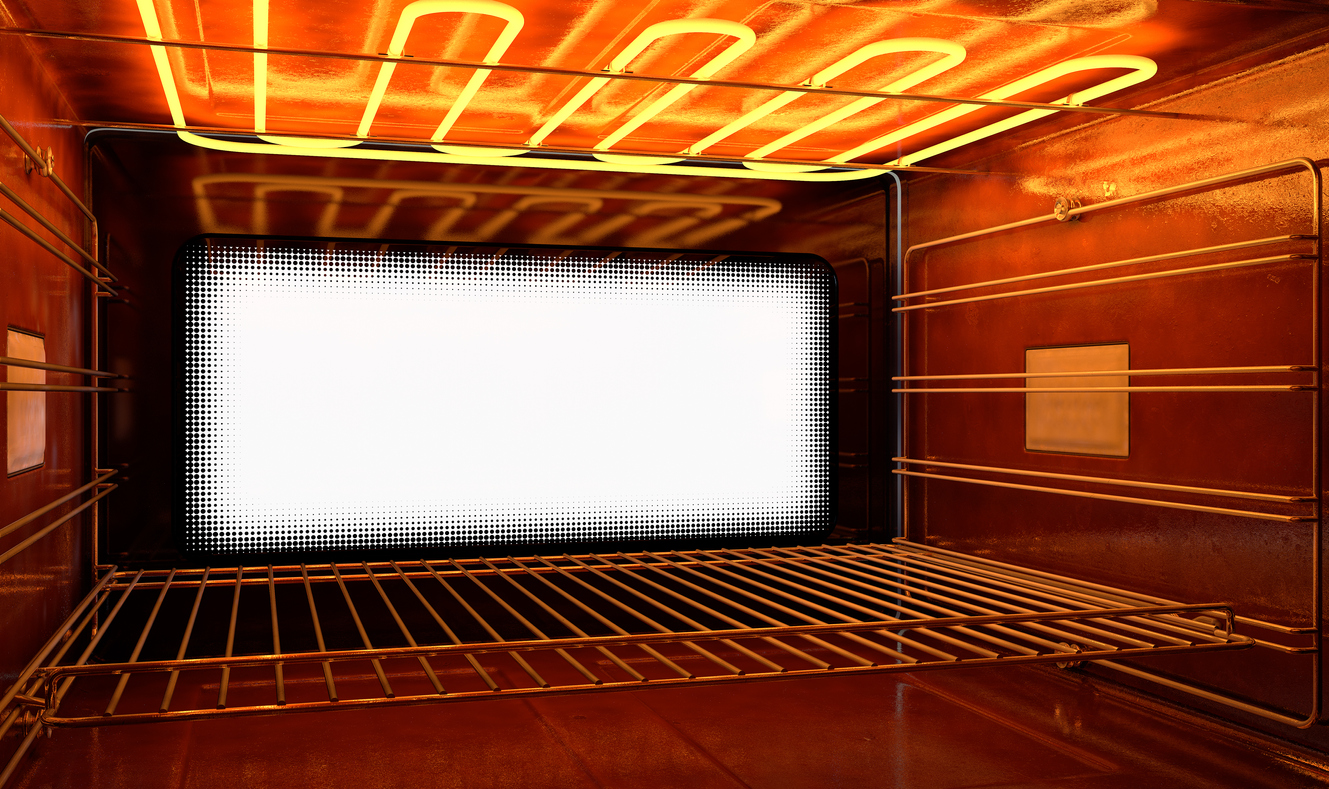

Thanks to this specific process, the glass takes on properties that make it usable effectively in domestic and professional ovens, as real barriers to the heat generated during cooking or during special cleaning cycles (pyrolytic)

The heat barrier level is measured with the Resistivity parameter (ohm/sqm).